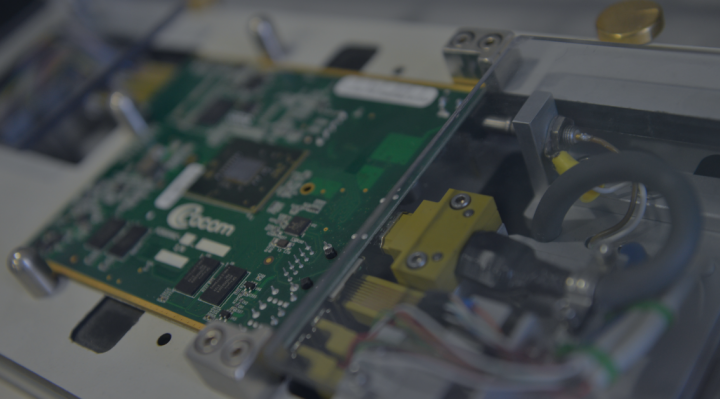

In the realm of Electronics Manufacturing Services (EMS), the concept of environmental responsibility is not just a trend but a crucial aspect of modern business practices. As industries evolve, the significance of implementing and maintaining robust environmental standards cannot be overstated. This brings us to the role of ISO 14001, a standard in environmental management systems, particularly in the context of EMS.

What is ISO 14001?

ISO 14001 is an international standard that outlines the requirements for an effective environmental management system (EMS). This standard is pivotal for companies in the EMS sector for several reasons. Firstly, it provides a framework that helps companies reduce their environmental footprint, enhancing their efficiency and effectiveness. By aligning with ISO 14001, companies can lower operational costs, thanks to the efficient use of resources and reduced waste. Moreover, adherence to this standard ensures compliance with various environmental regulations, which are particularly pertinent in the electronics industry.

ISO 14001 in the EMS Lifecycle

The implementation of ISO 14001 can be traced across three critical stages of the electronics manufacturing process: pre-production, production, and post-production.

Pre-Production: This phase involves planning and design, where environmental considerations like material selection and process efficiency are pivotal. Adherence to ISO 14001 ensures that these processes are eco-friendly and sustainable.

Production: At this stage, the focus of ISO 14001 is on minimizing waste and optimizing resource use. This is achieved by addressing issues like unnecessary machine operation, untrained staff leading to material wastage, and the production of non-compliant products that require reworking.

Post-Production: In this final stage, ISO 14001 guides the disposal and recycling of waste, ensuring minimal environmental impact.

Benefits of ISO 14001 in EMS

Adopting ISO 14001 in EMS offers multifaceted benefits:

Enhanced Efficiency: By identifying and addressing errors and waste, and through the proper training of personnel, ISO 14001 significantly boosts operational efficiency.

Waste Reduction: This standard helps in significantly reducing waste production, a critical factor in sustainable manufacturing.

Cost-Effectiveness: Efficient resource management and waste reduction inevitably lead to lower operational costs.

Environmental Impact: Compliance with ISO 14001 ensures that the environmental footprint of the manufacturing process is minimized.

Business Opportunities: As environmental consciousness grows among consumers and stakeholders, ISO 14001 certification becomes a valuable asset, opening doors to new business ventures and partnerships.

In summary

In today's environmentally-conscious market, ISO 14001 is more than a certification; it's a necessity for EMS providers. The electronics industry, with its significant environmental impact, must prioritize eliminating waste and reducing its footprint. In this context, ISO 14001 is not just a badge of honour but evidence of the company's commitment to sustainable and responsible manufacturing.